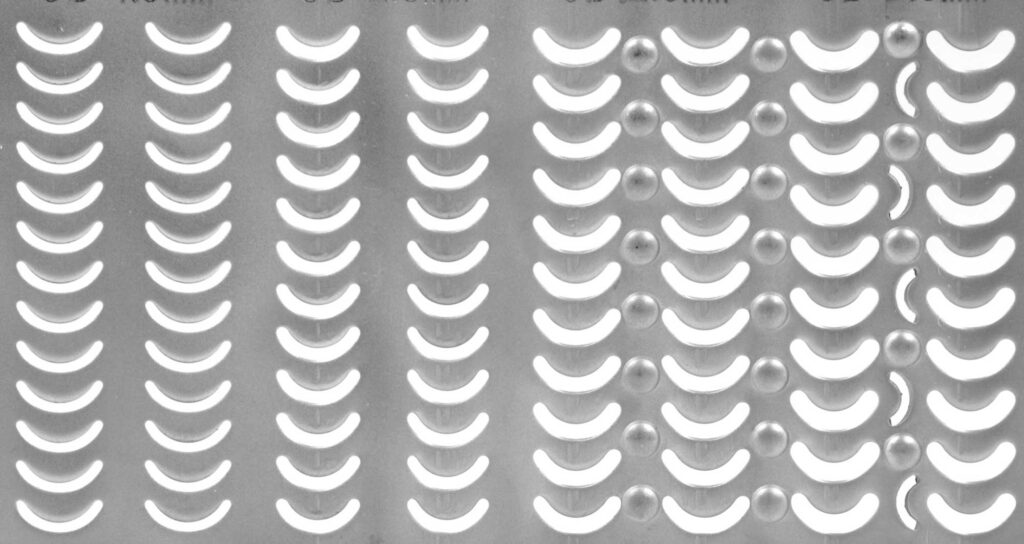

Sickle-hole sheet perforation

Advantages:

- Reduction of damage

- Reduction of lot mixing

- Reduction of adhesion with

- additional wash board surface (see photo)

- Optimal flow behaviour through sickle-hole sheet perforation

- Reduction of foam formation

- Better flow behaviour

- .

- No damage

Additional options are available for the Klotz sickle-hole sheet perforation, guaranteeing optimal performance for every application.

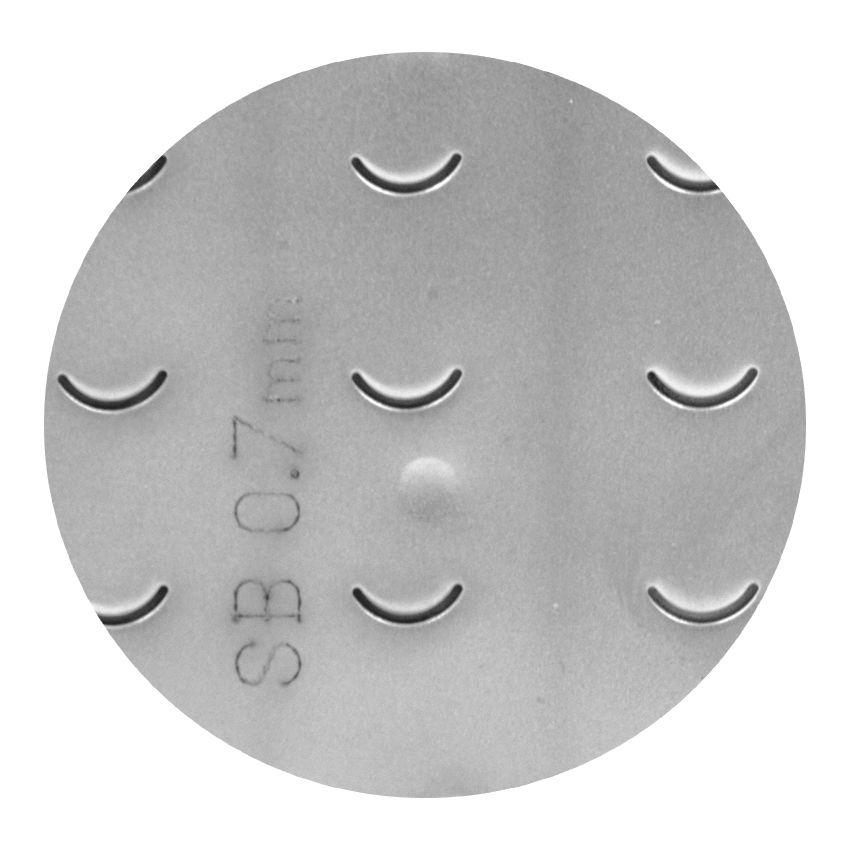

Wash board surface

Good media discharge through minimal surface area. Lot mixing of wire products is avoided. Particularly well suited for SPAX screws/nails. Damage to parts is avoided. The basket is robust and stable with a low weight. It has a single wall for easy cleaning. The time between cleaning cycles is longer. The service life is extended.

Wash board and double nub structure

The hole pattern is enlarged. The durability is further improved. Media displacement is further reduced and items cannot adhere. This prevents lot mixing

The process is patented (German patent no.: 102006008444)

Sickle-hole perforated sheet, offset

Advantages:

- Offset perforations in the inner and outer jacket

- Sickle-hole sheet perforations in the inner jacket with wash board structure

- Offset round holes in the smooth outer jacket

The process is patented (German patent no.: 102004001923)

Duplex sickle-hole perforated sheet

Advantages:

- Fine perforations are made in an overall large wall thickness

- Fine perforations in a thin-walled inner jacket

- Coarser perforations in a thick-walled supporting jacket

The process is patented (German patent no.: 10322895)

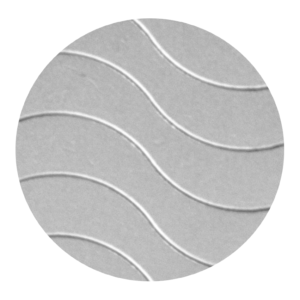

Sinusoidal perforation

Advantages:

- For very small parts

- Slot width from 0.15 to 0.25 mm in a sheet thickness up to 6 mm

Just like the perforation, the basket shape geometries are chosen especially for your application. Just like the perforation, the basket shape geometries are chosen especially for your application. The focus is always on the maximum volume and a basket optimised for weight.

Your way to the perfect washing basket, centrifuge inlay or coating inlay

In the following short questionnaire, you briefly explain the intended application for your basket/inlay to us online. We receive an e-mail. Then we can contact you and make you an appropriate offer. By submitting the completed questionnaire, you provide us with the key data.